Repairs to rudder

Repairs to Rudder

While towing my fuselage tail-first on a trailer, I thought I had secured the rudder but a passing truck created enough of a gust blast to rip my gust lock free and jam the rudder to one side so far that the rudder horn was bent on the other side. Here's the damage.

While towing my fuselage tail-first on a trailer, I thought I had secured the rudder but a passing truck created enough of a gust blast to rip my gust lock free and jam the rudder to one side so far that the rudder horn was bent on the other side. Here's the damage.

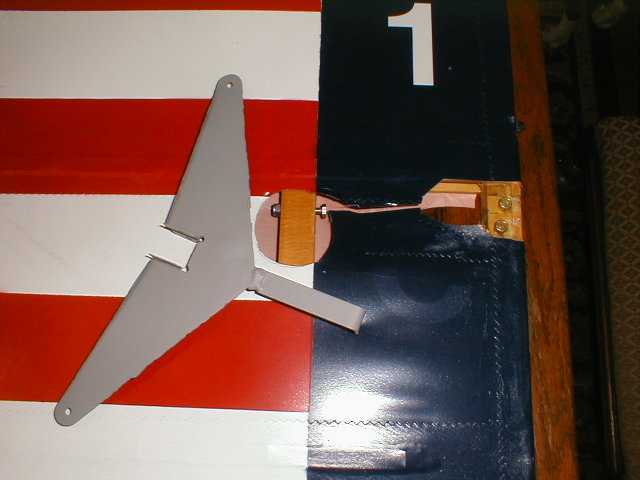

Here's another shot of the damage. Not quite a 45 degree bend, but enough to greatly worry me about how to fix it.

Here's another shot of the damage. Not quite a 45 degree bend, but enough to greatly worry me about how to fix it.

I would not rest easy with any sort of halfway fix on this one, so I took a razor knife to the fabric, opened up enough to allow me to free the horn, and then used various rods, bars, and wedges to straighten it back out again. With the part in the vise, I smoothed the damaged areas, inspected the welds, and had a master machinist watch over my shoulder through the whole process. Once the oval cross-section was re-established, the part was as strong as before. We sandblasted it, primed it, and reinstalled.

I would not rest easy with any sort of halfway fix on this one, so I took a razor knife to the fabric, opened up enough to allow me to free the horn, and then used various rods, bars, and wedges to straighten it back out again. With the part in the vise, I smoothed the damaged areas, inspected the welds, and had a master machinist watch over my shoulder through the whole process. Once the oval cross-section was re-established, the part was as strong as before. We sandblasted it, primed it, and reinstalled.

The other side. I only cut one side open enough to get the mounting hardware out. This side didn't need as large a hole but still needed patching.

The other side. I only cut one side open enough to get the mounting hardware out. This side didn't need as large a hole but still needed patching.

I cleaned the areas back to bare fabric, shaped fabric patches, glued them in place, built back up, then repainted the disturbed areas. I also got new vinyl tail numbers and redid both sides. Good as new. Here's how it looked with the patches complete up through silver. I flew it like this for return-to-service flight tests, then completed the paint and new tail numbers.

I cleaned the areas back to bare fabric, shaped fabric patches, glued them in place, built back up, then repainted the disturbed areas. I also got new vinyl tail numbers and redid both sides. Good as new. Here's how it looked with the patches complete up through silver. I flew it like this for return-to-service flight tests, then completed the paint and new tail numbers.

Voila! Good as new!

Voila! Good as new!